Stage of Development

Check in here to see where we are with development of the SPARCL.AI Platform

Revolutionizing Aviation Cleaning, Welding, and Marking

Advanced Robotic Solutions Integrated with Precision Lasers

Working for a Collaborative Partnership with:

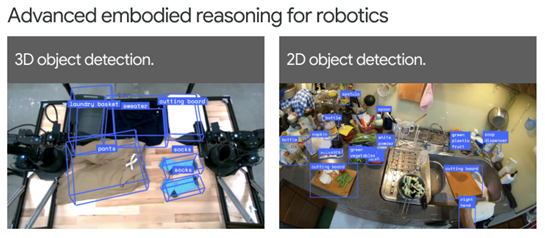

Gemini Robotics

Our most advanced vision-language-action (VLA) model

Our Gemini 2.0-based model allows robots to take action in the physical world.

Siasun robots are the market's top choice due to their technological innovation, multifunctionality, and adaptability. With advanced technology, they enhance work efficiency, facilitate human-robot collaboration, and free up human resources, boosting productivity and competitiveness for businesses.

FeatherPulseTM laser technology leverages high‑peak‐power pulsed fiber lasers and precision scanning optics to deliver a fast, chemical‑free, and substrate‑safe cleaning solution across a wide range of industrial and heritage‐conservation applications.

Our Vision

Leading the Future of Robotic Lasers

SPARCL is dedicated to revolutionizing industrial laser technology with advanced robotic solutions that enhance precision cleaning, welding, and marking and streamlining operations. Our team is committed to bringing aerospace technology to all areas of industry where precise affordable lasers is a must.

Exterior Paint and Coating Removal

Rolls-Royce confirms "This automatic laser cleaning process has replaced previous manual chemical cleaning of parts...

Turbofan Laser Cleaning

1. Principles of Laser Cleaning

Laser cleaning uses focused laser pulses to remove contaminants—such as soot, oxides, CMAS (CaO–MgO–Al₂O₃–SiO₂), and grease—from turbine engine components without abrasive media or chemicals. Key mechanisms include:

-

Photothermal/Photomechanical Ablation: High‑peak‑power pulses (10–100 ns) induce rapid thermal expansion and shockwaves, spalling off deposits while preserving the substrate [1](ScienceDirect).

-

Wavelength Selectivity: Near‑infrared (1064 nm) Nd:YAG fibers exploit stronger absorption by contaminants versus metal, maximizing cleaning efficiency [2](SSRN).

-

Assist Gases: Argon or nitrogen (1–5 bar) flows purge ablated debris and inhibit re‑oxidation during cleaning [1](ScienceDirect).

2. Research on Turbine Blade Cleaning

2.1 High‑Pressure Turbine (HPT) Blades

Studies on nickel‑based superalloy blades coated with Y₂O₃‑stabilized ZrO₂ show that continuous‑wave fiber lasers (power density ≈ 7.96 × 10^6 W/cm²) effectively remove CMAS deposits under argon, delivering clean surfaces with controlled roughness [1](ScienceDirect). Integration of pulsed and continuous modes further improves oxide removal quality and throughput [2](SSRN).

2.2 Compressor & Fan Blades

Surface fouling on compressor stages degrades aerodynamics; laser ablation can strip oxide scales and debris without altering blade geometry. Early work demonstrated no microstructural damage when parameters are optimized, confirmed via SEM and X‑ray analyses [6](kones.eu).

Laser‑Cleaning Sequence for Automation

-

Pre‑Inspection & Fixturing

-

Machine‑vision scans to map blade geometry and locate ribs/platforms.

-

Position robotic arm(s) with appropriate beam path.

-

-

Rib & Platform Cleaning

-

Use a focused scan pattern to traverse narrow rib channels first, eliminating debris that could shadow blades.

-

Parameter: moderate overlap, lower pulse energy to avoid nicking edges.

-

-

Compressor Fins & Fan Blades

-

Sweep the beam along blade spans, starting on the hub side and moving outward.

-

Parameter: higher repetition rates with continuous scanning for uniform coverage.

-

-

Turbine Blade Cleaning

-

Switch to assist‑gas purge (argon) to capture high‑temperature oxides and CMAS.

-

Employ multi‑pass strategy: first pass at lower power for photochemical ablation of organics/contaminants, second pass at higher power for oxide spallation.

-

-

Final Inspection

-

Post‑cleaning borescope and 3D laser profilometry to verify surface roughness and confirm no TBC or substrate damage.

-

Automated feedback loop adjusts parameters for next part.

-

By following this flow—and using a robotic arm equipped with adjustable-focus fiber‑laser delivery—you can automate precise cleaning of each component in the turbofan section. This approach minimizes human intervention, ensures repeatable coverage, and protects critical surfaces from thermal damage.

Advantages of SPARCL

Efficiency-driven Technology for Precision Lasers

SPARCL's advanced robotic solutions bring groundbreaking benefits that transform precision laser applications and optimize operational efficiency. Our cutting-edge technology ensures thorough and effective results, significantly cutting down on time and labor costs. Discover the power of our robots, engineered to handle even the toughest laser challenges with ease. Elevate your standards with SPARCL and achieve outstanding results in every project.

FeatherPulse’s family of fiber‑laser modules brings precision, power, and digital control to robotic automation—whether you’re cleaning, marking, or welding—by seamlessly integrating with modern robot controllers and AI‑driven platforms like Gemini Robotics and Siasun Robots:

-

Compact, All‑Fiber Design: Each laser head connects via a flexible fiber cable to a centralized source, minimizing wrist payload and preserving full robot articulation. No delicate free‑space optics to align means simple “plug‑and‑play” deployment in tight cell layouts.

-

Software‑Defined Beam Parameters: Pulse energy, repetition rate, and scan patterns are all set in software and exposed through standard industrial field‑bus or Ethernet interfaces. Gemini Robotics’ AI can dynamically tune these parameters in real time—adjusting cleaning intensity based on surface feedback or optimizing marking contrast on the fly.

-

Closed‑Loop Process Monitoring: Integrated power meters and backscatter sensors feed live data into the robot’s control loop. Siasun's platform leverages this feedback to verify cleaning depth or weld penetration, automatically compensating for part variation and ensuring consistent results.

-

Recipe‑Driven Automation: Pre‑configured “recipes” for specific materials and tasks simplify programming. Robotics engineers can call up a cleaning job or marking sequence by name, then let Gemini’s AI refine head speed and overlap to hit quality targets, while Siasun orchestrates start/stop triggers and safety interlocks.

-

High Uptime & Low Maintenance: Fiber lasers run cool and sealed, with lifetimes well into tens of thousands of hours. This reliability aligns with Siasun's “lights‑out” manufacturing vision—cells that can run unattended, only pausing robot motion for scheduled filter replacements or sensor calibrations.

By marrying feather‑light fiber heads with AI‑enabled control and robust robot integration, this laser suite empowers Gemini and Siasun systems to automate surface prep, part identification marks, and even light welding or cutting operations with single‑micron precision and enterprise‑grade uptime.

Efficiency

-

Software‑defined beam parameters and high‑peak‑power pulses enable rapid material interaction, letting robots clean surfaces or mark parts in a single pass rather than multiple cycles.

-

The all‑fiber design and “plug‑and‑play” integration minimize setup time and eliminate daily optics alignments, so robotic cells spend more time producing and less time idling.

Cost Savings

-

Longer fiber‑laser lifetimes and sealed optics drastically reduce maintenance and consumable expenses compared to abrasive or chemical cleaning systems.

-

Recipe‑driven automation slashes programming and qualification effort—once a process is dialed in, the same parameters can be deployed across multiple cells without repeat trials.

Safer Process

-

Non‑contact cleaning and marking remove the need for hazardous chemicals, grit media, or UV lamps—operators face fewer exposure risks and waste streams are purely particulate.

-

Integrated interlocks, real‑time power monitoring, and seamless robot communication ensure lasers only fire when the tool head is correctly positioned, reducing stray‑beam and pinch‑point hazards.

Our Core Solutions

Elevating Precision Robotic Lasers

Discover our extensive array of services aimed at enhancing precision laser operations. We specialize in cutting-edge robotic laser ablation technology, along with advanced welding and marking solutions. Our commitment is to empower your success in the realm of industrial robotic lasers. Let us help you achieve new heights your laser applications.

Robotic Laser Welding

Experience the power of robotic laser technology and discover how it can enhance precision cleaning, welding, and marking to optimize your laser needs.

Advanced Laser Cutting

Explore our innovative cleaning solutions designed to improve the overall cleaning experience and operational outcomes.

FeatherPulseTM Laser Cleaning

Optimize your cleaning operations with our advanced solutions, ensuring efficient workflows and streamlined processes.

Environmental Safety

Prioritize environmental safety with our solutions to make laser operations safer for the environment and technicians. By combining chemical‑free ablation with efficient power use and closed‑loop particulate capture, FeatherPulseTM automation supports both sustainable manufacturing and strict environmental‑safety standards.

Key Features

Innovative Technology Platforms for Precision Robotic Lasers

Discover the innovative features of our robotic laser solutions, crafted to provide complete control over precision laser cleaning, welding, and cutting operations. With the power of AI-driven robotics and real-time monitoring, achieve unparalleled precision and efficiency in your laser. Experience seamless integration that boosts your productivity and elevates your operations. Embrace the future of laser robotics technology!

Real-time Monitoring

Introducing our mobile robotic laser system, expertly designed for welding, cleaning, and marking applications. Equipped with a state-of-the-art three-dimensional vision system, this innovative technology ensures precision positioning and enhanced accuracy. With integrated RFID capabilities and advanced obstacle avoidance, our robotic solution operates seamlessly in dynamic environments, delivering efficient and reliable results for your manufacturing needs. Experience the future of automation with our cutting-edge mobile laser technology.

Seamless Integration

How Gemini AI Robotics, Duco Robotics and FeatherPulse fiber‑laser modules come together to form a tightly‑integrated, turnkey automation ecosystem:

1. Unified Control Architecture

-

Common Communication Backbone: All three systems speak the same industrial “language,” relying on standard Ethernet/IP or ProfiNet connectivity. Gemini’s AI orchestration layer, Duco’s cell‑controller PLC, and the FeatherPulse laser’s onboard controller share a deterministic network, eliminating protocol converters or custom drivers.

-

Single‑Pane Monitoring: Operators and maintenance staff access one dashboard that displays robot kinematics, cell safety status, and live laser parameters. Underneath, a microservice‑based API aggregates data from the laser heads (power, pulse rate, scan pattern), the robot arms (position, speed), and Duco’s safety I/O modules (door interlocks, e‑stop).

2. Recipe & Job Management

-

Centralized Recipe Database: Cleaning, marking and welding “recipes” live in Duco’s central server. Each recipe bundles laser settings (energy, frequency, overlap), scan geometries, robot tool‑center‑point (TCP) paths, and quality‑check thresholds. When Gemini kicks off a new job, it simply references the recipe ID—no manual hand‑offs.

-

Version Control & Audit Trails: Every parameter tweak is logged, with user, timestamp and change rationale. If an engineering change requires a new weld‑penetration depth or marking contrast, you clone the recipe, adjust settings in Duco’s web UI, and publish. Gemini AI then rolls out the update across all cells tagged for that part number.

3. Real‑Time Closed‑Loop Feedback

-

Sensor Fusion: FeatherPulse heads embed backscatter photodiodes and acoustic‑emission sensors. As the laser pulses, these sensors stream data back to Duco’s PLC and Gemini’s AI engine. Algorithms compare live signals against “gold‑standard” fingerprints, confirming when cleaning is complete or marking depth is within tolerance.

-

Automated Compensation: When part geometry varies—say a slight curvature shift—Gemini instantly adjusts robot speed or laser repetition rate. If the backscatter signal plateaus early, signaling a stubborn coating, Duco’s controller slows the scan until the particulate signal drops below threshold.

4. Safety & Compliance

-

Integrated Safeguarding: Duco’s certified safety relay blocks laser firing unless all door interlocks, area scanners and robot‑wrist encoders report safe conditions. Gemini AI can pause or abort the job if a human enters the cell or a torque spike suggests a collision risk.

-

Standards Alignment: The entire system complies with ISO 13849 (machine‑safety), ANSI Z136.1 (laser safety) and CE directives. Safety‑rated network switches separate the safety I/O channel from production traffic, so emergency stops cut power to both robot and laser in under 10 ms.

5. Commissioning & Scalability

-

Plug‑and‑Play Cell Roll‑Out: New cells arrive with pre‑installed Duco safety cabinets, Gemini‑certified robot mounts, and FeatherPulse head brackets. Factory acceptance tests validate network handshakes, recipe uploads and feedback loops—so on‑site commissioning is reduced to path‑tuning and part‑fixture validation.

-

Modular Expansion: Whether you need a cleaning‑only bay today or plan to add marking and welding later, the same infrastructure scales. Gemini’s AI scheduler dynamically assigns jobs across available lasers, Duco’s server auto‑provisions new recipe slots, and the fiber‑laser heads simply plug into spare ports on the existing laser source.

By harmonizing field‑bus communication, centralized recipe management, real‑time sensor feedback, and safety‑first architecture, the trio of Gemini Robotics, Duco Robotics and FeatherPulse lasers delivers a truly seamless automation platform—minimizing integration risk, maximizing uptime, and ensuring consistent, enterprise‑grade quality.

Advanced Reasoning

Leverage predictive analytics to anticipate cleaning trends and optimize resource allocation, driving better cleaning outcomes.

AI-powered Gemini 2.0 Robotics

Unlock the full potential of Gemini Robotic AI and Siasun Robotics with our advanced FeatherPulseTM Laser technology. Experience unparalleled precision and in laser processes, setting a new standard in robotic laser integration and operations. Together, we are leading the industry into a future of innovation and excellence.

Smart

Photonic

Aviation

Robotic

Cleaning

Laser

AI Generated Graphic (obviously)